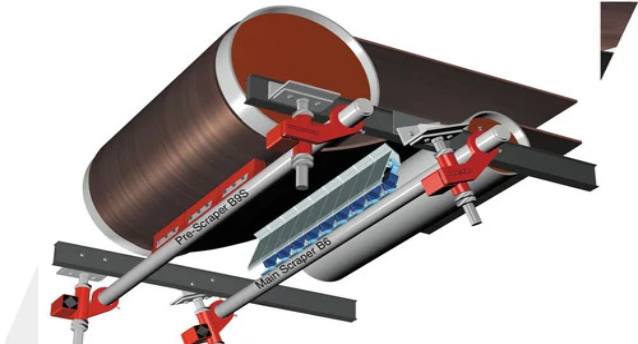

Scrapers and Spares.

Scrapers with PU Blades (Primary) and Tungsten carbide blades (Secondary) provide superior cleaning efficiency. Those are also feature a lower lifetime cost—due to their durability. When you consider lifetime cost vs. initial cost, Hosch scrapers durability and lower required maintenance often makes up the cost difference over the life of the blade.

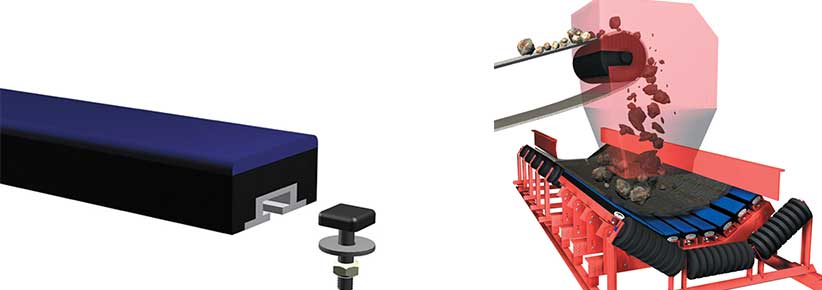

Impact pads .

Providing the perfect solution: The Tega Friflo Impact Bed system is manufactured to provide the support to the belt against the free-falling lumps. Furthermore, it comes as a replacement for impact rollers, which require high maintenance, thanks to the reduction in moving parts. The low friction feature of the UHMWPE always ensures smooth conveyor movement, with minimal wear-and-tear of the belt bottom cover. The design of the structural frames is customized with FEA simulations on the basis of operation parameters at the site.

Skirt sealing system and Spares.

Loading station spillage, cleaning manpower engagement and poor air quality Providing the perfect solution: The Tega Spill-Ex skirt sealing system provides the best solution when it comes to sealing the belt at the conveyor loading zone. Adjustable to sync with the profile of the belt, it can compensate for the gap created by the belt sagging, thereby providing an effective seal to the entire loading zone.

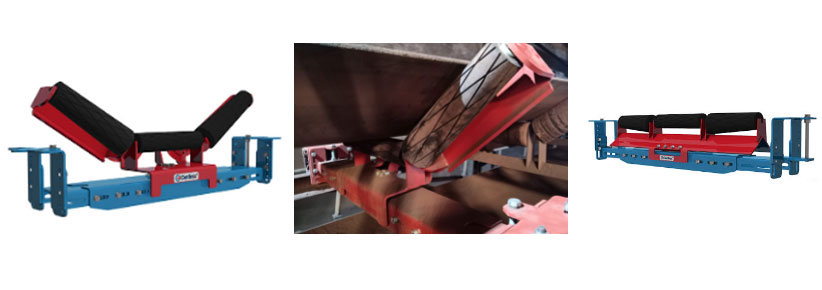

Belt conveyor Sway control Rollers .

Belt sway, belt edge damage and unscheduled shutdowns resulting from tripping of belt Providing the perfect solution: The specially-designed tapered side rollers make CenTrax sensitive to the slightest belt sway. The two-bearing pivot system allows the entire Tracker roller to move forward bringing the belt back on track and performs ideally under heavy duty conditions. The CenTrax standard trough and the return trackers along with CenTrax V roller and inverted tracker rollers bring the belt back on track. The rollers are completely rubber lagged and diamond grooved to ensure the generation of a higher traction force. The most prominent feature of this quality product is its easy installation and maintainability, thanks to it replaceable roller system. The three-piece system is designed in such a way that it can be adjusted vertically, horizontally and to any desired angle.

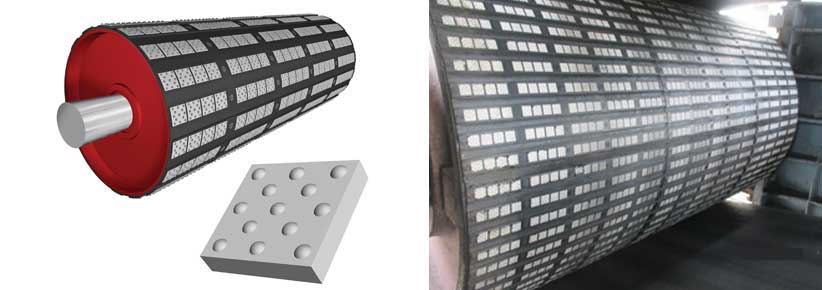

Ceramic Pulley Lagging.

Belt slippage over conveyor pulley drum. Providing the perfect solution: The Tega Slip-Ex Ceramic Lagging effectively protects the pulleys by eliminating slippage. The specially designed ceramic tiles with nubs improves the belt traction. The Tega ceramic pulley has found widespread usage on drive pulleys, snub pulleys, bend pulleys, tail pulleys, take-up pulleys and, also in certain cases, pressure pulleys.